- New products

- Sold Out

- Abrasives

-

Clamps

- Malleable cast iron screw clamp TG with 2-component plastic handle

- Heavy duty malleable cast iron sctrew clamp TGK with 2-component plastic handle

- Malleable cast iron screw clamp TG with tried-and-true wooden handle

- Heavy duty malleable cast iron screw clamp TGK with tried-and-true wooden handle

- Malleable cast iron screw clamp TG with tommy bar

- Heavy duty malleable cast iron screw clamp TGK with tommy bar

- Malleable cast iron screw clamp TPN with 2-component plastic handle

- Malleable cast iron screw clamp TPN with tried-and-true wooden handle

- Heavy duty malleable cast iron screw clamp TKPN with tried-and-true wooden handle

- Heavy duty malleable cast iron screw clamp TGKR with tried-and-true wooden handle

- Malleable cast iron deep throat screw clamp TGNT with tried-and-true wooden handle

- Malleable cast iron deep throat screw clamp TGNT

- All-steel screw clamps GZ with 2-component plastic handle

- All-steel screw clamps GZ with swivel handle

- All-steel screw clamps GZ with tried-and-tested wooden handle

- All-steel screw clamps GZ with tommy bar

- All-steel screw clamps classiX GS with tried-and-tested wooden handle

- All-steel screw clamps classiX GS with tommy bar

- OMEGA all-steel screw clamp GMZ with 2-component plastic handle

- OMEGA all-steel screw clamp GMZ with tommy bar

-

Power tools

- Festool 18 V promotion

- Cordless circular saw

- Cordless jigsaws

- Cordless sanders

- Cordless drills-screwdrivers

- Cordless dust extractors

- Cordless hammer drills

- Cordless angle grinder

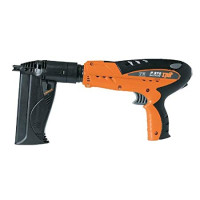

- Cordless nailers and staplers

- Cordless Oscillating / Multi-Tools

- Cordless reciprocating saws

- Cordless blowers

- Cordless caulking gun

- Cordless insulating-material saws

- Working light / speakers

- Cordless speakers and radio

- Battery packs and chargers

- Accessories

- Kreg tools

-

Nailers and staplers

- Balancers and retractors

- Concrete and steel fixing

- Fixing systems

- Wood repairing

- Cleaning products

-

Cutting tools

-

Hand tools

- DeWALT tools and accessories

- Washing and cleaning equipment

- Coating materials

- Varnishing, painting equipment and tools

- Personal protection equipment

- Measuring tools

-

For Garden and Home

- Ladders, ladder accessories

- Scaffolding and staging

- Fan shop

Description

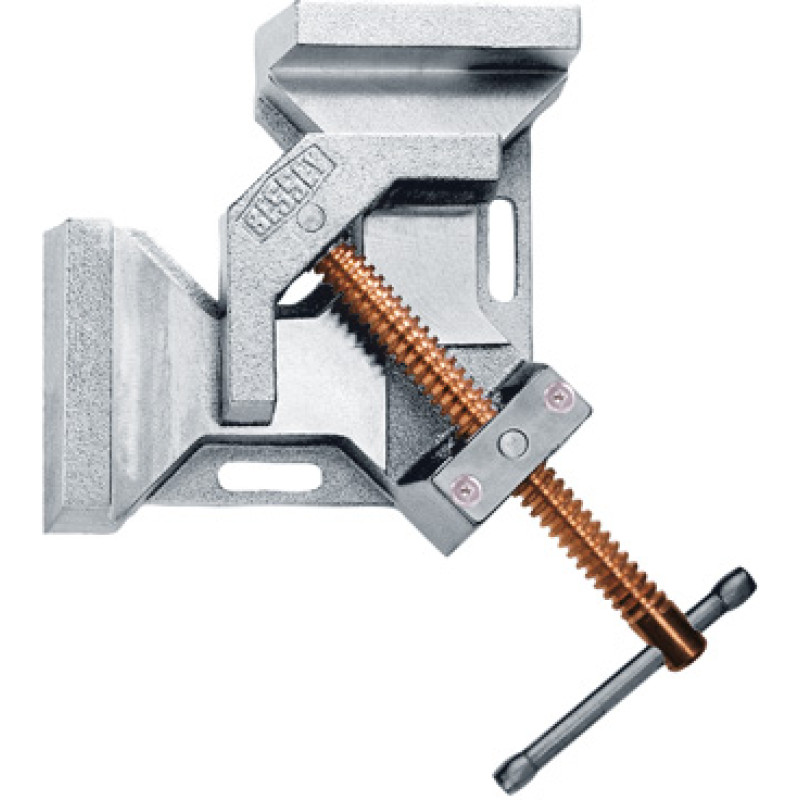

Metal angle clamp

- Automatic adjustment to workpieces of various thicknesses

- Sturdy jaws and base plate made from high-quality cast iron

- The copper-plated spindle prevents welding splatter from sticking

- Precise 90°-angles

BESSEY has developed the WSM welding angle clamp especially for use in steel construction, welding and metalworking. Its wide range of applications includes holding, fixing and aligning workpieces at an exact right angle. The clear working area means that you can access the workpiece unhindered during welding and assembly work, and when fixing T-joints.

The BESSEY WSM welding angle clamp is a high quality tool for welding exact corner joints. It can be attached to machining and welding tables via two slot holes. Unhindered access to the workpiece makes welding and assembly work easier.

BESSEY has two sizes of welding angle clamps. The clamping width on both sides is 90 mm for the WSM9 and 120 mm for the WSM12. T-joints can also be fixed thanks to the maximum open passage of 60 mm for the WSM9 and 100 mm for the WSM12.

Even workpieces with different thicknesses can be aligned at an exact right angle. This is because the spindle nut with an articulated bearing allows automatic adjustment for different work piece thicknesses.

The spindles with Acme threads are copper-plated on the WSM welding angle clamp. The copper plating prevents welding spatter adhesion. The welding angle clamp's base and clamping jaws are made of high-quality cast iron and are galvanised. These treatments protect them against corrosion and allow powerful clamping.

Technical data

- Opening - 2 x 120 mm

- Current passage maximum - 100 mm

- Weight - 7,80 kg

Downloads

*The images of the Products displayed on the Website are for illustrative and informative purposes only. The picture of the goods may differ from the actual packing size and appearance of the goods and the images may show parts that are not included in the delivery of the goods

Pamanījāt kļūdu? Ziņojiet mums

Pamanījāt kļūdu? Ziņojiet mums