- New products

- Sold Out

- Abrasives

-

Clamps

- Malleable cast iron screw clamp TG with 2-component plastic handle

- Heavy duty malleable cast iron sctrew clamp TGK with 2-component plastic handle

- Malleable cast iron screw clamp TG with tried-and-true wooden handle

- Heavy duty malleable cast iron screw clamp TGK with tried-and-true wooden handle

- Malleable cast iron screw clamp TG with tommy bar

- Heavy duty malleable cast iron screw clamp TGK with tommy bar

- Malleable cast iron screw clamp TPN with 2-component plastic handle

- Malleable cast iron screw clamp TPN with tried-and-true wooden handle

- Heavy duty malleable cast iron screw clamp TKPN with tried-and-true wooden handle

- Heavy duty malleable cast iron screw clamp TGKR with tried-and-true wooden handle

- Malleable cast iron deep throat screw clamp TGNT with tried-and-true wooden handle

- Malleable cast iron deep throat screw clamp TGNT

- All-steel screw clamps GZ with 2-component plastic handle

- All-steel screw clamps GZ with swivel handle

- All-steel screw clamps GZ with tried-and-tested wooden handle

- All-steel screw clamps GZ with tommy bar

- All-steel screw clamps classiX GS with tried-and-tested wooden handle

- All-steel screw clamps classiX GS with tommy bar

- OMEGA all-steel screw clamp GMZ with 2-component plastic handle

- OMEGA all-steel screw clamp GMZ with tommy bar

-

Power tools

- Festool 18 V promotion

- Cordless circular saw

- Cordless jigsaws

- Cordless sanders

- Cordless drills-screwdrivers

- Cordless dust extractors

- Cordless hammer drills

- Cordless angle grinder

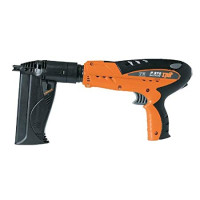

- Cordless nailers and staplers

- Cordless Oscillating / Multi-Tools

- Cordless reciprocating saws

- Cordless blowers

- Cordless caulking gun

- Cordless insulating-material saws

- Working light / speakers

- Cordless speakers and radio

- Battery packs and chargers

- Accessories

-

Nailers and staplers

- Balancers and retractors

- Concrete and steel fixing

- Fixing systems

- Wood repairing

-

Cutting tools

- DeWALT tools and accessories

-

Hand tools

- Cleaning products

- Washing and cleaning equipment

- Coating materials

- Varnishing, painting equipment and tools

- Personal protection equipment

- Measuring tools

-

For Garden and Home

- Ladders, ladder accessories

- Scaffolding and staging

- Fan shop

Description

Press Release – The grip plier range from BESSEY

Pliers that can do more than just open the jaws

- Parallel jaw faces

- Prism recess for small round parts

- Includes pressure caps for gentle clamping of sensitive surfaces

BESSEY grip pliers are an ideal aid for all-round or full-surface clamping, or for fixing workpieces which are next to one another. This is because the jaws on the pliers are infinitely adjustable and parallel to each other in every position, or at the desired angle to one another, thus avoiding cumbersome adjustments to the workpiece size. And the best thing is: The clamping force that is set using an adjusting screw remains constant over the entire clamping range.

BESSEY grip pliers have special technical refinements. Using them makes day to day working life much easier for many users in the metalworking industry - they work quicker and more safely.

In the Parallel grip GRZ, the clamping jaws remain parallel to each other in the entire clamping range. The slotted screw on the handle can be used to adjust this by 9° in both directions. Both clamping surfaces have a toothed profile and the bottom surface also has a groove to clamp small round parts. Protective caps to gently clamp delicate surfaces are also supplied as standard. The GRZ is available in two sizes: with a clamping width of 100 or 200 mm, each with a throat depth of 65 mm.

If pin-point and full-surface clamping on both sides is required, the C-grip GRZC is absolutely ideal. This is because the clamping arms are bent, which enables a clamping depth of 40 mm per clamping arm. The clamping width is 110 mm and the throat depth is 80 mm.

If you want to clamp workpieces with different thicknesses or offset workpieces, the assistance of the Variogrip GRZV is indispensable. Its sliding arm is not just bent for clamping depths of up to 43 mm, but is also split into two parts. Both parts can be infinitely adjusted independently of each other, by an opening width of up to 100 mm and a throat depth of 50 to 80 mm.

The Pipe grip GRZRO is an ideal solution for welding pipes of the same size to each other. Round components with diameters of up to 110 mm can be fixed neatly thanks to the infinitely adjustable, forked clamping arms with prism supports and a throat depth of 65 mm. The gap between the forks provides unhindered access to the welding point. A protective cap set is supplied as standard to machine stainless steel pipes, e.g. in railing construction. The two straight protective caps are pushed onto the pressure plates on the sliding arm; the two v-shaped protective caps are placed onto the fixed arm's prism from above and latched in. The protective caps are made of fibreglass-reinforced polyamide and temperature resistant up to 200 °C, which is completely sufficient for joining pipes. The grip pliers are then normally released and the pipes welded all around. The protective cap's wide contact surface on the v groove is also very helpful when clamping smaller parts.

Technical data

- Clamp opening - 100 mm

- Throat depth - 65 mm

- Weight - 1,00 kg

Downloads

*The images of the Products displayed on the Website are for illustrative and informative purposes only. The picture of the goods may differ from the actual packing size and appearance of the goods and the images may show parts that are not included in the delivery of the goods

Pamanījāt kļūdu? Ziņojiet mums

Pamanījāt kļūdu? Ziņojiet mums