- New products

- Sold Out

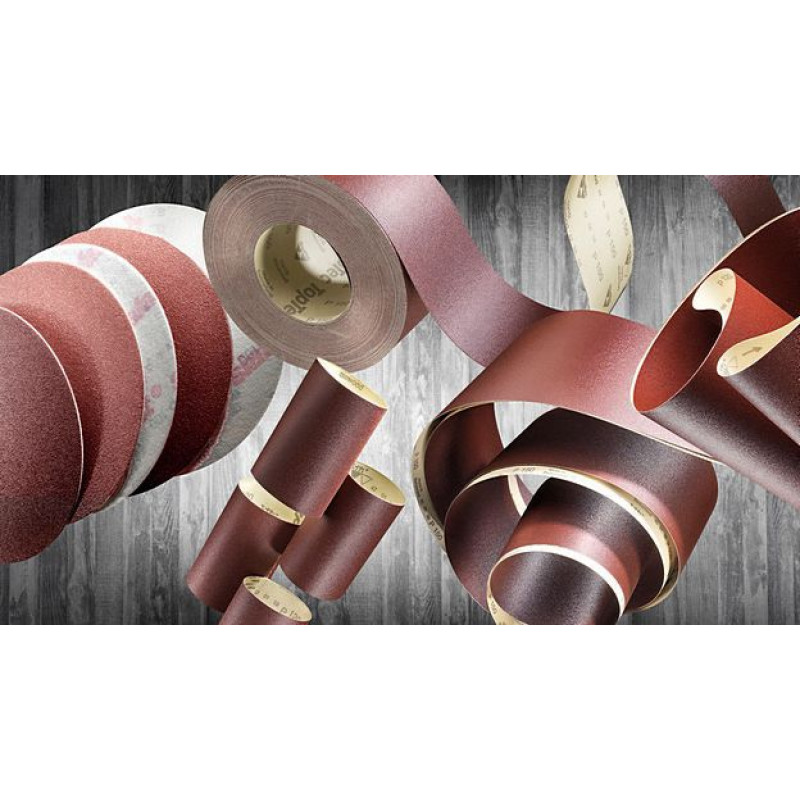

- Abrasives

-

Clamps

- Malleable cast iron screw clamp TG with 2-component plastic handle

- Heavy duty malleable cast iron sctrew clamp TGK with 2-component plastic handle

- Malleable cast iron screw clamp TG with tried-and-true wooden handle

- Heavy duty malleable cast iron screw clamp TGK with tried-and-true wooden handle

- Malleable cast iron screw clamp TG with tommy bar

- Heavy duty malleable cast iron screw clamp TGK with tommy bar

- Malleable cast iron screw clamp TPN with 2-component plastic handle

- Malleable cast iron screw clamp TPN with tried-and-true wooden handle

- Heavy duty malleable cast iron screw clamp TKPN with tried-and-true wooden handle

- Heavy duty malleable cast iron screw clamp TGKR with tried-and-true wooden handle

- Malleable cast iron deep throat screw clamp TGNT with tried-and-true wooden handle

- Malleable cast iron deep throat screw clamp TGNT

- All-steel screw clamps GZ with 2-component plastic handle

- All-steel screw clamps GZ with swivel handle

- All-steel screw clamps GZ with tried-and-tested wooden handle

- All-steel screw clamps GZ with tommy bar

- All-steel screw clamps classiX GS with tried-and-tested wooden handle

- All-steel screw clamps classiX GS with tommy bar

- OMEGA all-steel screw clamp GMZ with 2-component plastic handle

- OMEGA all-steel screw clamp GMZ with tommy bar

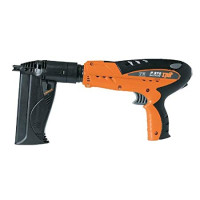

- Nailers and staplers

- Kreg tools

- Halder soft-face mallet

- Picard hammer

-

Power tools

- Cordless circular saw

- Cordless jigsaws

- Cordless sanders

- Cordless drills-screwdrivers

- Cordless dust extractors

- Cordless hammer drills

- Cordless angle grinder

- Cordless nailers and staplers

- Cordless Oscillating / Multi-Tools

- Cordless reciprocating saws

- Cordless blowers

- Cordless caulking gun

- Cordless insulating-material saws

- Working light / speakers

- Cordless speakers and radio

- Battery packs and chargers

- Accessories

- Balancers and retractors

- Concrete and steel fixing

- Fixing systems

- Wood repairing

- Cleaning products

-

Cutting tools

-

Hand tools

- DeWALT tools and accessories

- Washing and cleaning equipment

- Coating materials

- Varnishing, painting equipment and tools

- Personal protection equipment

- Measuring tools

-

For Garden and Home

- Ladders, ladder accessories

- Scaffolding and staging

- Fan shop

Description

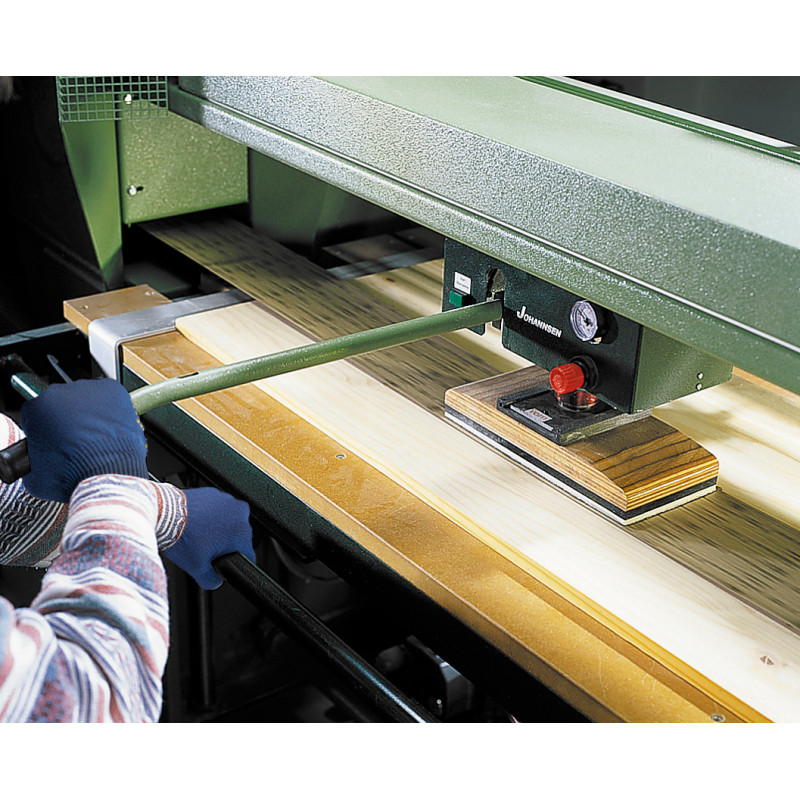

The benchmark for wood sanding

The latest generation of the classic 1919 siawood sets new standards in stationary wood sanding. Produced from the highest-quality raw materials in one of the world’s most state-of-the-art abrasives manufacturing plants, 1919 siawood+ meets the highest demands of the woodworking industry and the professional trades. Its maximum process stability is the result of a consistently high removal rate and perfect Swiss surface quality over the entire lifetime of the abrasive

- Premium product for the highest quality demands in stationary wood sanding

- Minimal clogging thanks to modern coating technology

- Outstanding performance and long life

- Very high abrasive performance with a good finish

- Backing with very high stability and rigidity

- Lower grinding costs due to longer lifetime

Technical data

- Sanding belt size, width x length - 0120 x 2250 mm

- Grit size - P0100

- Grit - blue-fired aluminium oxide

- Backing - f-wt paper

- Coating - open

- Bonding - synthetic resin

- Equipment - TopTec

Applications

- Calibrating surfaces

- Coarse sanding of solid wood and wood-based materials

- Fine sanding of solid wood, veneers and wood-based materials

Materials

- Softwood

- Hardwood

- Resinous wood

- Solid surface material

- Plastics

- Bodyfiller

- Primer filler

Superior belt joints

- Best manufacturing quality and high-quality consistency

- Excellent sturdiness and long life

- Comprehensive, solution-oriented belt joint concept

- Many years of know-how thanks to sia Abrasives Engineering

Best antistatic properties

- Less cleaning required, less wear and a longer lifetime of equipment thanks to reduced dust accumulation in machines and assemblies

- Better work conditions due to minimized dust in the ambient air

- Longer belt life and greater durability due to low level of clogging

Consistent quality

- Quality products “Made in Switzerland”

- High-precision, laser-controlled and ultrasound-monitored measurement procedures for consistent product quality and exceptional quality reliability

Removal rate / Sanding performance

The efficiency of an abrasive is largely dependent on the sanding performance, and therefore the removal rate when calibrating or finishing solid wood and wood-based materials. Premium quality, bluefired aluminium oxide and controlled grit coating have enabled us to increase the removal rate of our 1919 siawood+ by another 20%. Your advantage: The higher sanding performance of 1919 siawood+ shortens your sanding process and increases your productivity.

Clogging / Lifetime

The lifetime of an abrasive is primarily determined by the resistance to clogging when sanding wood – especially resinous softwood. State of-the-art, controlled coating technology on the Maker 5 has provided a significant increase in lifetime. Your advantage: The new-generation 1919 siawood+ enables you to sand for up to 30% longer than with the tried-and-tested 1919 siawood – for maximum productivity and process stability!

Sturdiness / Tear resistance

A sanding belt is subjected to especially high stress when calibrating or edge sanding. The more sturdy and resilient the sanding belt, the less likely it is that belt tears and unproductive downtimes will occur. For this reason, we have further strengthened our 1919 siawood+ by approximately 15% in the P36 to P80 grit range. Your advantage: Reduced risk of belt tears and unproductive downtimes thanks to one of the sturdiest paper backings on the market.

Safety recommendation

- Pay attention to the abrasives safety data sheet (available from sia Abrasives)

- Follow the general FEPA safety recommendations

- Use eye and face protection

- Use an effective dust extraction unit or wear a fine dust mask

*The images of the Products displayed on the Website are for illustrative and informative purposes only. The picture of the goods may differ from the actual packing size and appearance of the goods and the images may show parts that are not included in the delivery of the goods

Pamanījāt kļūdu? Ziņojiet mums

Pamanījāt kļūdu? Ziņojiet mums

-800x800.jpg)