- New products

- Sold Out

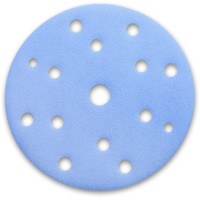

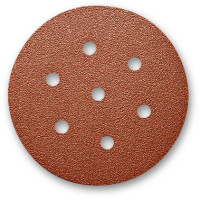

- Abrasives

-

Clamps

- Malleable cast iron screw clamp TG with 2-component plastic handle

- Heavy duty malleable cast iron sctrew clamp TGK with 2-component plastic handle

- Malleable cast iron screw clamp TG with tried-and-true wooden handle

- Heavy duty malleable cast iron screw clamp TGK with tried-and-true wooden handle

- Malleable cast iron screw clamp TG with tommy bar

- Heavy duty malleable cast iron screw clamp TGK with tommy bar

- Malleable cast iron screw clamp TPN with 2-component plastic handle

- Malleable cast iron screw clamp TPN with tried-and-true wooden handle

- Heavy duty malleable cast iron screw clamp TKPN with tried-and-true wooden handle

- Heavy duty malleable cast iron screw clamp TGKR with tried-and-true wooden handle

- Malleable cast iron deep throat screw clamp TGNT with tried-and-true wooden handle

- Malleable cast iron deep throat screw clamp TGNT

- All-steel screw clamps GZ with 2-component plastic handle

- All-steel screw clamps GZ with swivel handle

- All-steel screw clamps GZ with tried-and-tested wooden handle

- All-steel screw clamps GZ with tommy bar

- All-steel screw clamps classiX GS with tried-and-tested wooden handle

- All-steel screw clamps classiX GS with tommy bar

- OMEGA all-steel screw clamp GMZ with 2-component plastic handle

- OMEGA all-steel screw clamp GMZ with tommy bar

-

Power tools

- Festool 18 V promotion

- Cordless circular saw

- Cordless jigsaws

- Cordless sanders

- Cordless drills-screwdrivers

- Cordless dust extractors

- Cordless hammer drills

- Cordless angle grinder

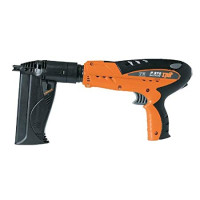

- Cordless nailers and staplers

- Cordless Oscillating / Multi-Tools

- Cordless reciprocating saws

- Cordless blowers

- Cordless caulking gun

- Cordless insulating-material saws

- Working light / speakers

- Cordless speakers and radio

- Battery packs and chargers

- Accessories

-

Nailers and staplers

- Balancers and retractors

- Concrete and steel fixing

- Fixing systems

- Wood repairing

-

Cutting tools

- DeWALT tools and accessories

-

Hand tools

- Cleaning products

- Washing and cleaning equipment

- Coating materials

- Varnishing, painting equipment and tools

- Personal protection equipment

- Measuring tools

-

For Garden and Home

- Ladders, ladder accessories

- Scaffolding and staging

- Fan shop

Description

Perfect conformability to workpiece

When sanding with foam abrasives, the focus is not only on removing as much material as possible. It is vital to achieve an absolutely smooth and even result when preparing surfaces for subsequent painting or varnishing. If the goal is to achieve a perfect workpiece surface finish with low scratch depth, applying pressure in two dimensions when sanding (such as using conventional sandpaper) is not enough, for example when using paper-backed abrasives. Instead, pressure needs to be applied in three dimensions. Force can be applied in three dimensions by using the foam as the carrier material in connection with a flexible binder resin. This allows the grit to dissipate the contact pressure along a Z-axis.

Features

- The abrasive grit does not cut into the material as deeply and breaks off less

- As such, less material is removed and no sanding through of the material occurs at the edges

- Instead, we achieve a homogeneous surface

- Perfect conformability to workpiece, even in hard-to-reach areas

- No surface damage due to creasing

- Due to their conformability, foam abrasives are the ideal choice for areas that are difficult to access and have profiled surfaces

- Hard-to-reach areas, such as door handle depressions, bumpers and radiator grilles, are ideal fields of application for the siasponge

- Unlike conventional sandpaper, foam abrasives can be folded without creating permanent creases, which allows a consistent sanding pattern due to improved grain consistency without swirl marks.

Technical data

- Size: 120 x 97 x 12 mm

- Cover: 2 sides

- Grit: Coarse (roughly corresponds to surface quality P80 - P120)

- Grain: Aluminium oxide

- Material: PU (polyurethane)

*The images of the Products displayed on the Website are for illustrative and informative purposes only. The picture of the goods may differ from the actual packing size and appearance of the goods and the images may show parts that are not included in the delivery of the goods

Pamanījāt kļūdu? Ziņojiet mums

Pamanījāt kļūdu? Ziņojiet mums